|

| |

|

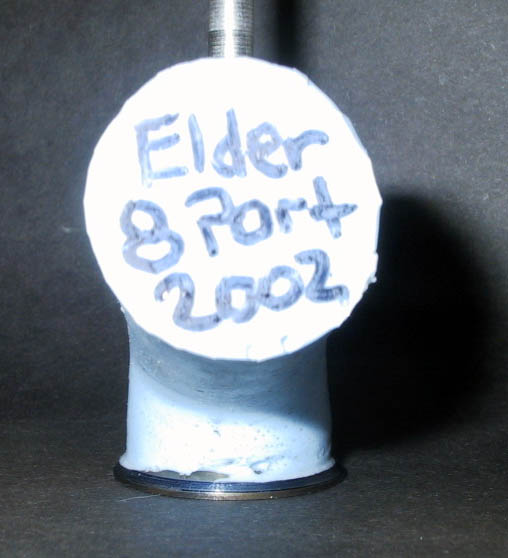

Silicone Rubber

Port Cast |

| Here's a cast of the inlet port from the

Elder 8-port aluMINIum cylinder head. The process starts by coating the

inlet port with a very thin layer of Vaseline, then inserting the valve

with just the inner spring to hold it in place. Following the instructions

for the rubber, simply pour it into the port, vacuum to remove trapped

air, then set it aside for 16 hours. After removing the valve, I push the

cast out with the ram of my milling machine using a wooden dowel on the

business end. With a moderate amount of effort, the cast extrudes out the

throat without damage or distortion.

The silicone rubber material I use is made by http://www.smooth-on.com/liqrubr.htm

and it is supplied by a local plastics shop. It's pretty cheap too, for

$40 CND I got enough of the Mold Max 30 to do 20 casts of this size.

Click on each picture below for a closer look. These

castings were taken from the first casting that was shipped to me. Because

of some disappointing flow data it was sent back and replaced with a new

casting that flows much better. The short radius that appears fairly tight

here has been widened out considerably.

|

|

|

|

|

|