EFI 8-Port Project

This is a quick-and-dirty place holder page for this project. I'll do a

better one when I have time |

|

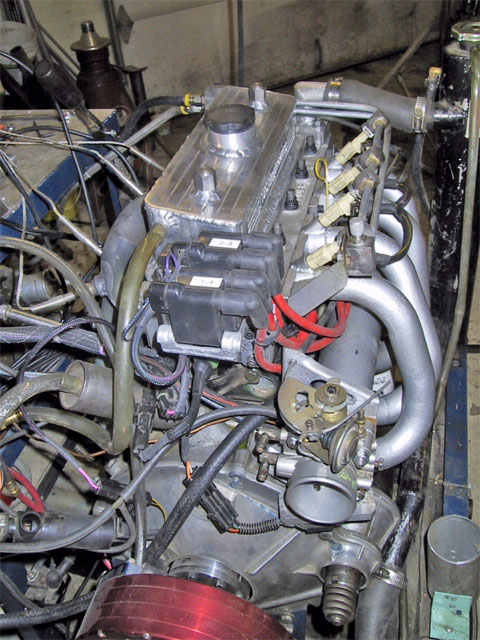

This is the original concept for the inlet manifold. The

starting point was a manifold from a mid-90's Ford Escort. Unfortunately

this did not leave clearance for the bonnet, so a decision was made to

move the plenum down parallel to the block. Since full engine

management will be used, there is no distributor to interfere. |

|

Flanges were made from 1"x3" bar stock, then the manifold

started with 1.125" U-bend tubing. |

|

The plenum is sheet steel, rolled into a log with belled ports in the

floor. Because the ports are splayed and angled up from the block the fuel

rail was a bit of a challenge. Injector bosses were made from bar stock,

drilled on an angle then lined up on 5/16" ridged tubing before they

were silver soldered in place. |

|

The rocker cover supplied by Elder is not very refined and it needed a

considerable amount of grinding to clear the 1.5:1 rockers. I thought it

would be less work if I just made my own. Of course, I was wrong, but the

end result is nice!

Instead of dealing with those horrible cork gaskets, a 1/8" groove

was cut in the base flange so an O-ring could be inserted. It's cheap,

won't move around and absolutely will not leak. Why don't they all do it

this way? |

|

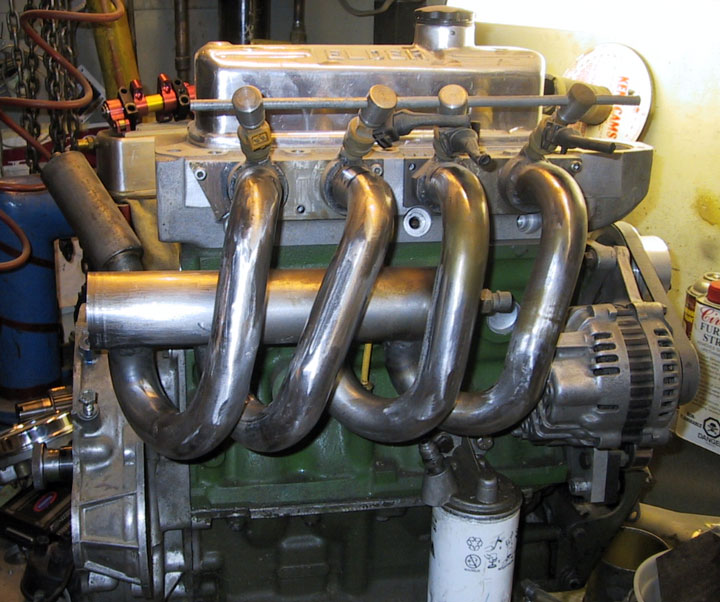

The manifold is designed with 18" of runner length, which my

calculations say will resonate at around 3000 RPM to give a nice flat

torque curve. The runners will clear the grille of a round nose Mini.

The throttle body is 50 mm Mazda, the coil pack is from Hyundai and the

injectors are Bosch 220 cc/min. |

|

Here's the finished product. You can hear it running here

Yes, that is a waterbrake dynamometer hanging off the clutch end. Time

did not permit acquisition of any meaningful power data, but 2007 is

another year. |

|

This is an older photograph of the 200 Hp Land and Sea snowmobile dyno.

Updates have been the addition of a data acquisition system that records

EGT on all 4 branches, two channels of O2, crank position, RPM, system

temperature and, of course, torque. The DYNOmite torque arm with it's

single bridge strain gauge has been replaced by a full bridge strain gauge |

|

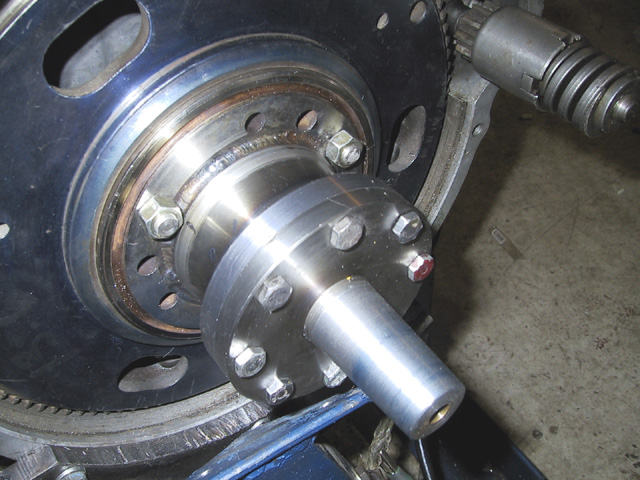

Before you Email me to ask how the dyno is driven, here's the adaptor to

get from a Mini crank taper to the snowmobile taper. All these parts were

fabricated in the garage workshop. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|