| The amazing disappearing

GT body. It was rusty, crusty and had moss growing on the paint! Too bad

to salvage but an excellent donor to transmogrify the low milage Deluxe into

the GT it always wanted to be. |

|

| So, which wheels look better?

The self-serve auto wrecker is a fantastic source of bits for restoration

projects. There's no end to the number of 5x13 'rally' style wheels from

early Mustang II or Pinto and occasionally a Capri comes along complete with

5.5x13" mags. I'm still looking for one of those with an 'uprated' Kent engine.

The car on the right came from

the wrecking yard! Yep, we picked it up for $300 CDN. It has covered just

38,000 miles. It required only minor repairs to the rear wheel arches

|

|

| It's time to reveal my sources.

Here's the links to my suppliers.

More links to come... when I

have time to compile them all.

|

Burton

Power

- engine, gearbox and brake parts

Past Parts

- hard to find brake and suspension parts

Dave Bean Engineering

- North American supplier of Ford parts

Pierce Manifolds

- maker of aluminum heads and manifolds

Car

Orphanage

-suspension bushings

ARP Fasteners

- rod bolts, head bolts... proper stuff

Leda Suspension

- they make MK II strut inserts EXACTLY like the originals.

|

Progress report 1 - June

The GT shell has gone on to its

new life as a soup can or Honda, drivetrain is out of the new shell, the

GT engine, gearbox, rear axle and suspension are all stripped, sandblasted

and powder coated.

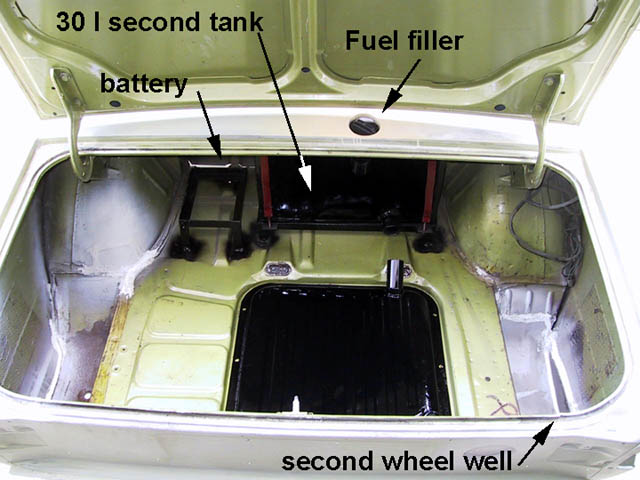

Most of June has been spent in

the boot as you can see on the right. It now has 70 l fuel capacity and room

for 2 spare tyres.

|

I

I |

Progress report 2 - July

In the back seat area I've installed

an aluMINIum bulkhead and plated in the side panels too. This week (July

9) it's off getting the roll cage installed

|

|

Progress report 3 - August

In the life of a project there's

always that gratifying moment when it turns that corner and starts actually

IMPROVING! That is usually when the primer goes on signifying the end to

major body work. Only minor dinging left to do then blocking the primer before

paint.

|

|

| Whod'a thunk these wheels

came from the bone yard for $5 ea? Of course that doesn't account for the

$20 to have them chemically cleaned and $25 to have them powder coated. I've

changed the wheel studs to the size used by full-size Ford's: 1/2"

Funny, for $5 I could buy a whole

Pinto with 4 or 5 wheels.

|

|

Progress report 4 - September

All the engine, gearbox, brake

and suspension bits necessary for the restoration arrived within the last

few weeks so it's time to get some real work done!

These Kent engines are pretty

finicky to setup especially when changing the cam to one with higher lift

and duration, plus changing the pistons and head to the uprated style.

I also went for the Pierce aluminium head which is where most of the work

was done. First step was to dry fit the engine with the new pistons fitted

to the block but not much other machining done. This step was necessary

to ensure there was 0.060" clearance between the valves and piston crown.

I had to take an additional 0.030" off the valve pockets in the piston

crown plus widen them for the bigger valves. A home machine shop is invaluable

when it comes to fiddly work like pocketing pistons. Even with a jig to

hold the piston on the milling machine bed there were still 4 different

setups to do the cutting and it took most of a day. With that done the

bottom end went back to the machine shop for crank grinding and balancing

of all the rotating bits. The crank then went out for liquid nitriding.

The top end wasn't so straight

forward. The Pierce head is a copy of the stock uprated head except in

aluminium so working with it is a joy. My engine shop punched out the seats

to take 1.60" x 1.34" valves after which I opened up the throats to about

89% of the valve size, cleaned up the ports and matched the twin Weber

manifold. On dry fitting the springs I found that the locating cups are

machined too small for the springs Kent supplied. A jig, consisting of

a stud bolted to the milling machine bed, was used to center the guide

under the boring head and with 8 quick setups the locating cups were large

enough. It's a good thing I made a jig because I had to go back once more

and lower the spring platforms 0.030" to get the minimum clearance between

spring coils.

|

Cutting the valve

spring platforms wider and deeper to fit the springs supplied with

the Kent 234 cam kit

Cutting the valve

spring platforms wider and deeper to fit the springs supplied with

the Kent 234 cam kit

|

It doesn't take very

long to cut the platforms with a boring head.

It doesn't take very

long to cut the platforms with a boring head.

|

| Holidays are

a marvellous thing especially when you don't have to go anywhere and you

can stay in the shop doing what you want to do, like blitz the suspension,

brakes, gearbox and engine! Rear axle is in, front suspension, except the

struts (I'll wait for the adjustable bits to arrive) is in, gearbox and

engine are in! Now, where did I put those Weber's? |

It hasn't been this

clean in 30 years!

It hasn't been this

clean in 30 years!

|

There's nothing like

working with clean parts on a clean car

There's nothing like

working with clean parts on a clean car

|

|

Home at last. The

engine that came out of this shell is pretty much garbage, this GT engine

sat for 10 years before this major rebuild. In this picture you can see

the twin 40 DCOE's stuck on so I can figure out what air filters I need

to get, the old wiring harness cut open and roughed in so I can start

modifying it for the 75 amp Hitachi alternator and the headlamp relay

bank. The brake master cylinder is from a Ford Ranger truck.

|

There aren't many aspects

of restoration that I don't enjoy, but blocking primer is one. It's tedious,

physically demanding and difficult to determine when you are actually

finished. The body shop that did the final paint said this was in the

top 2% of the cars they've seen come in for their 'mask and spray' service.

This is simultaneously gratifying and disconcerting. Gratifying because,

well, everybody likes to have their ego stroked once in a while, but

disconcerting because I did the work in my shop with nothing more than

a hammer, dolly, body file and $10 worth of wet/dry sandpaper. It begs

the question, what do they do to earn so much??

There aren't many aspects

of restoration that I don't enjoy, but blocking primer is one. It's tedious,

physically demanding and difficult to determine when you are actually

finished. The body shop that did the final paint said this was in the

top 2% of the cars they've seen come in for their 'mask and spray' service.

This is simultaneously gratifying and disconcerting. Gratifying because,

well, everybody likes to have their ego stroked once in a while, but

disconcerting because I did the work in my shop with nothing more than

a hammer, dolly, body file and $10 worth of wet/dry sandpaper. It begs

the question, what do they do to earn so much??

|

|

This is the final update for 2001.

Winter is coming to the land of the Wild Goose which means

the garage space has to be cleared for parking the wimpy

car, so the Cortina is back in storage with the other

'diamonds in the rust'. Since it was painted in September

the following have been accomplished:

|

Electrical system

has been redone, relays, bigger fuse block, rally lights, electric fan and rear defrost added |

|

All the glass

reinstalled - what a crappy job that is! |

|

Tower brace

fabricated, suspension installed and settings roughed

in |

|

Headliner made

(thanks Jane!) and installed |

|

Wheel arch liners

made and installed |

|

Chrome cleaned up

and installed |

|

a bazillion little

problems that crop up from a car sitting for decades

have been cleaned up |

In the spring, it seems

like such a long way off, I'll get the Webers on and the

engine fired, the brakes bled and exhaust system made.

After about a week's worth of work it should be moving

under its own power. After I get the sump and tank shields

built it will be time for shake down runs on the gravel

roads in central Alberta. Stay tuned!!

|