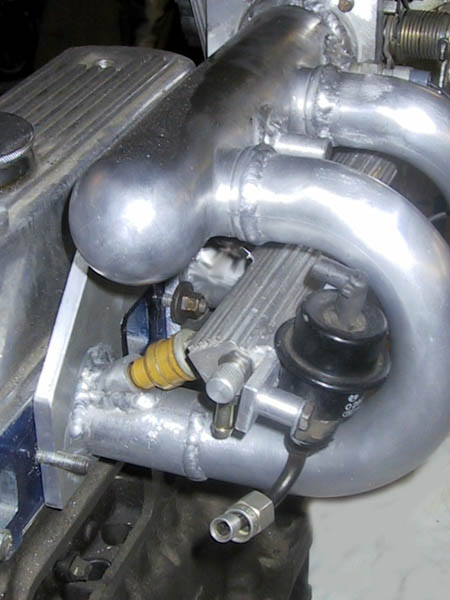

| Here's my first shot at the

project. The manifold is 14 ga aluminium hammer formed, in halves, over an oak

buck, then butt welded together. I

aimed the throttle body over the rockerbox where I was going to make a plenum

that lead to the air filter somewhere down in front, maybe even ram air? The air plenum is 1/4" plate. It never

got finished because when I got to this point I realized there wasn't enough

room for the fuel rail! I could make something that would work, but there

wasn't really enough room to get it in and out to change injectors. Sigh, into

the scrap bin and start again. |

|

| Here's the second attempt. A '95 Ford Escort

donated the cast aluminium plenum and 180 degree 'bananas'. I started by

cutting off the 4 bananas, the flanges on the head and the flange for the

throttle body. The Ford uses a tiny 32 mm throttle body which I left in

the junk yard. No wonder those things are so SLOW! |

|

| Once I had a pile of useful parts I made the

flange for the head. With the plenum, throttle body and fuel rail all hanging

off the flange, I figured I would extend the plate against the head up high

enough that I could pickup the plenum. The extension for the ports is drawn

heavy wall aluminium tube, the injector bosses are made from bar stock as is

the fuel rail.

The fuel pressure regulator is a Bosch OEM piece used on GM

3.0 V6 and operates at 3 Bar.

Injectors are laid back as far as I could. They aim at the

port floor just upstream of the port divide.

|

|

| With the head side of the manifold mocked up I

cleaned up the plenum so the original bananas fit back in where they came

from. Interestingly, Ford 'soldered' the manifold together. The material

holding the formed bananas to the cast plenum and flanges is an alloy with

slightly lower melting temperature. It's all easy enough to machine, but when

it comes to TIG welding there's a lot of junk in there! |

|

|

I used 2 holes in the plenum to feed the head,

one for the manifold air temperature (MAT) sensor (Delphi) and the last for a

vacuum take off to feed the fuel pressure regulator and manifold absolute

pressure (MAP) sensor (Delphi too).

The 55 mm throttle body is from a Mazda 626. There's a

50 mm

body of identical design, from a Mazda 323, just in case the larger one

doesn't deliver enough throttle sensitivity down at the bottom end.

A Ford V8 donated the throttle position sensor.

|

|

On this end of the engine is

| a home brewed 48 tooth timing wheel with 4K spline

belt drive |

| Rennex (Renault Alliance) variable reluctance sensor

for crank position sensing |

| 4K spline belt water pump pulley - from aluminium bar

stock |

| Nippon Denso (Toyota) 75 amp alternator hard mounted to block |

| idler pulley made from 4130 bar stock (it's what I have

in the scrap bin!) |

|

|

Here's the engine :

| lightened steel flywheel and backing plate with blue (80

ft-lb) spring |

| wedged, polished and nitrided crank |

| +0.020 Hepolite 21251 pistons |

| Lightened and polished rods |

| Pierce aluMINIum head |

| Minisport 1.5:1 roller rockers |

| Kent 266 cam |

| home brew 4K spline pulleys for water pump and crank

(with timing teeth) |

|

|

Four views of the engine installed in the test

stand. Clockwise from left top:

| Engine side - the clean look |

| My control side - Laptop jacked into ECU, dyno control on

the left, analogue instruments on the apron. The rad swirl pot drain is

aimed right at my foot! |

| The system side - on the shelf is the 5 l fuel tank, a 1

l surge tank, low and high pressure pumps and filter. Immediately behind

the engine is the rad and electric fans |

| The clutch side - battery tucked into a corner away from

the exhaust. The ECU sits beside the tank. On top of the clutch

housing is the coil pack. |

|

|

| A couple of quick detail views showing the

location of the coil pack (left) and where ALL the action is (right). It's all

about aluMINIum ain't it? Almost everything in this picture was made in the

last couple of months in my workshop. What you can't see is the two oxygen

sensors in the LCB branches. One for outside cylinders and one for inside.

|

|

Hear

it run! Yes, it does did run, but with all the challenges presented by the

siamese port head, it only runs ran well within a small rev range. This sound clip

was done with 200 cc/min injectors so it runs well at idle up to 3000 RPM

after which it drops the outside cylinders. The 500 cc/min injectors can run up to

5000 RPM, but it wouldn't idle because the pulse width got down to the

reaction time limit of 2.5 ms.

First off let me say that the DTA ECU is fantastic. Itís

easy to use, does just what it is designed to and does it very well. If you

are planning on injecting an engine other than one with a siamese port head, I

would strongly recommend a DTA. If you are expecting plug-and-play youíll be

disappointed but perseverance will pay off. On the downside, their manual and

help files are written by a techie who assumes you know how everything is

supposed to work so if you have a problem itís entirely up to you to figure

it out. The Email support I got from DTA in England wasnít terrific, OK if

truth be told, it was always curt, not very helpful and occasionally rude. Which is better than

the response I got from their Canadian agent who seemed completely

disinterested in dealing with customers. That is, when he bothered to answer

the phone at all.

DTA market their system as being applicable to BMC A series

engines. They took an extremely simplistic approach to the problems presented

by the siamese port head, stating that all thatís required is "run it in

2-stroke mode and Bobís yer uncle". If the siamese cylinder cycles were

360 crank

degrees apart that would work just fine, but, unfortunately for us, they are

only 180 degrees apart and draw through the port asymmetrically. DTA have

never

set up an A series engine and do not know anyone who has, so

claiming it would work was a bit of a stretch. Between April and June 2002 I spent an

unreasonable amount of time conducting tests to search out the operating

envelope for this engine, continually updating DTA on my progress.

Unfortunately they didnít take too much of an interest in my work and

offered few suggestions on how to resolve problems. It was clear that they did

not understand the problem, or just didnít care enough to think about the data I was sending them.

Pitty.

Without fundamental changes to the DTA ECU it will not work

for siamese port engines. Since DTA were unwilling to make the

modifications I suggested, they offered to take their system back for

a full refund.

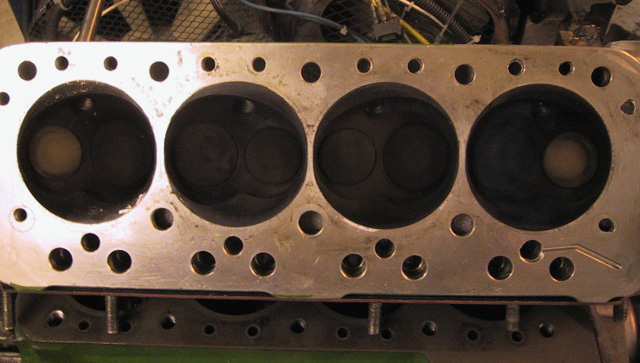

This photo probably tells the story best. The last time the

engine ran it was with injectors too big to work at idle, so it's showing a

lot of soot, but the #1 & 4 exhaust valves were running much hotter than

#2 & 3. This just confirms what I was seeing on the O2 sensors: it wasn't

running balanced.

|

|

This project is now being reworked as an 8-port EFI. The 5-port

manifold is on the shelf in hopes that someday one of the ECU manufacturers

will follow up on my research and actually rework their software to make it

work. DTA can't be bothered and although Emerald showed quite a bit of

enthusiasm, they have since stopped replying to Email. Curious.

As of February 2003 I am working on the inlet manifold for

the Elder 8-port. I'll completely redo this page when I have that done and I'm

a bit closer to getting the thing running again. Yes, it will be using the DTA

ECU. When you come right down to it, it's a very good unit and it will work

just fine on the conventional head.

I'm also exploring the possibility of using a Land and Sea

dyno on my test stand. These things are quite reasonably priced and

although I only really need a load to rough in the fuel and ignition map, they

can supply a load cell and readout so I can log torque and integrate BHP.

Gotta raise some real live US Greenback currency though. Watch for stuff on

Ebay!

|

| Linques!

|