|

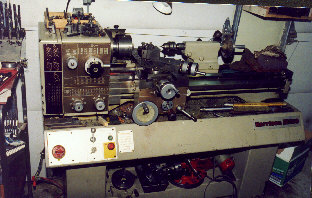

This is my Harrison M250 lathe. It's a 1984 model, but was installed in

a Government shop and was therefore little used. I had to change the motor

to a 220/1ph but otherwise it needed nothing but tooling. I just love this

machine! |

|

|

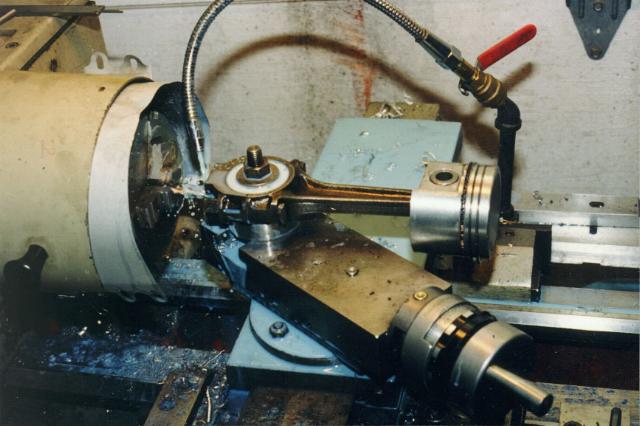

Here's a jig to hold clutch backing plates on the lathe while they're

pared down by 2 lb. The jig indexes the plate every 120 degrees to give it

that kinda triangular shape. The plate can also be centered for knocking

the back off or facing the friction surface. |

|

|

And here's what the plate looks like when it's done. At 4.4 lb it's

well within the 'safe' limit. |

|

|

Here's a solid centre flywheel which has had 4 lb taken off. At 13.8 lb

it's well within the 'safe' limit' |

|

|

Here's the latest mod for my distributors. I've installed needle roller

bearings (3/4" OD x 1/2" ID x 3/4" long) in the distributor body and made

a new shaft with an OD of 0.498". This solves a lot of the shaft movement

problems and with Luminition solid-state ignition, the spark is dead

accurate. |

|

|

Here's another jig used for lightening those grossly overweight 1300

rods.I use a 1/2" ball end mill cutter to put a slot across the balancing

pad, then round the thing over and shape it nicely. This doesn't reduce

the weight much, but every little bit counts. |

|

|

Here's a crank being tapered on the lathe. It's already been wedged on

the mill. This process only takes about 2 lb off the piece, but the

polishing process eliminates stress concentration sites. After the

polishing is done, it gets nitrided, leaving a nice satin black finish. |

|

|

My 500lb workbench made from 4x4x0.25" angle iron with a steel top, a

bay for the air compressor (left) and 2 huge drawers for rags. Scrap

stainless sheet was liberally utilized. Free is good!! The A-frame engine

hoist is designed to straddle the bench so engines can be picked up and

dropped effortlessly. NOTE! The bench is unusually TIDY!! |

|

|

The bench has 2 roll out carts designed to support engines during iccy

tear downs. The shelves underneath are for the casings and other bits, but

while the Cooper S is all torn apart, this area is for storage of

goodies. |

|

|

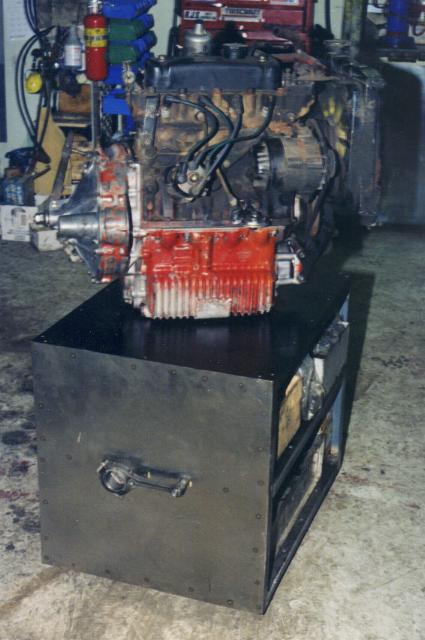

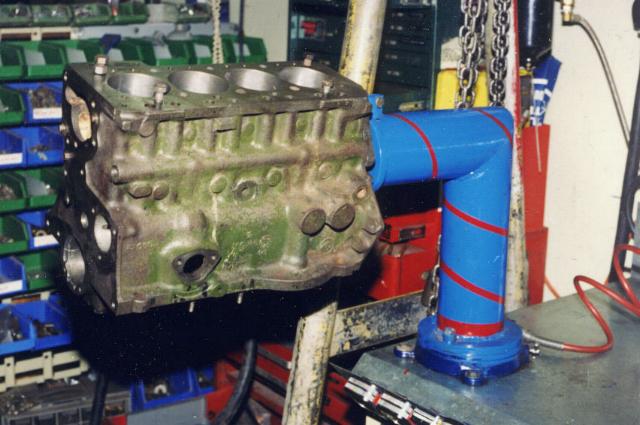

In the corner of the bench is this custom A series engine stand. It's

made from 4" diameter, 1/4" wall, steel tube. There's an axle in the head

which makes rolling the engine upside-down a snap. The base sucks. I made

it from a rotating base for a vice, but it is too light for the torque

being applied, so I'll be making a new one from 1/2" steel plate and

bearings. |

|

|

A deadwheel drive for the Halda odometer. I managed

to find several 8:1 worm gear sets, but the pitch centre is larger than

the Halda stuff, so I had to make my own housing. Works like a damn and

because the gears are hardened steel they should last

forever. |

|

|

Hereís a look at the corner of my shop in May 2002 with my new milling

machine in place. Itís a Bridgeport clone with power quill feed, power

traverse and DRO. It sits right beside my Harrison M250 and I donít know

how I ever worked without either of these! On the right is the engine test

stand, details for which you will find on my EFI project

page. |

|

|

|

| A new window for the attic

space in the garage |

|